Wiwynn Drives a Bottom-Up AI Culture with Profet AI, Rapidly Cultivating AI Talent

Wiwynn Drives a Bottom-Up AI Culture with Profet AI, Rapidly Cultivating AI Talent

Wiwynn, specializing in solutions for hyperscale data centers and cloud IT infrastructure, counts Meta, Microsoft, and other major U.S. cloud service providers (CSPs) among its primary customers. Benefiting from the widespread adoption of cloud applications, Wiwynn has experienced rapid revenue growth in recent years.

To provide these customers with highly efficient, low-energy consumption solutions for large-scale computing and storage, fast data transmission, and hardware-software integration, Wiwynn adopts an Original Design Manufacturer (ODM direct) model. This approach delivers customized server motherboard designs, production, and assembly services tailored to customer workloads.

“Improving efficiency and agility is very important to us,” emphasized Dr. Bey Yu, Director of Information and Digital Technology at Wiwynn. Following the company chairman’s directive from five years ago, Wiwynn has pursued a “top-down strategy and bottom-up execution” to drive digital transformation. This includes fostering an “AI-for-All” approach, encouraging employees to embrace digital tools, and establishing an End User Computing culture.

Complex Product Engineering and Resource-Intensive Quotation Process Streamlined by AI

As an ODM direct business, Wiwynn often faces labor-intensive and complex quotation processes whenever customers request quotes.

Yu explained that customer inquiries usually involve new product developments, specifying configurations and expectations while requesting quotes from Wiwynn. Upon receiving such requests, the company needs to send the specifications to all relevant units, asking them to identify and quote components meeting customer requirements. These components range from large items like product casings, metal and plastic parts, to smaller ones like cables and connectors on motherboards. The accumulated costs of these components significantly influence the final quotation. A well-done quotation results in profits; conversely, overly high quotations scare customers away, while low quotations lead to losses.

“Quotation often consumes a lot of our manpower,” Yu said. A single product quotation typically requires weeks of information gathering from multiple layers, followed by senior sales staff estimating reasonable quotes. This process is far from agile.

Thus, when Wiwynn decided to implement AI in early 2024, improving the quotation process became a key initiative. With the assistance of AI models, the relevant departments could more efficiently estimate optimal components and prices, reducing the quotation process time by 30%. Moreover, Wiwynn aims to digitize domain knowledge—previously reliant on a few senior employees—using the AI platform to accelerate talent development across departments.

Yu cited an example involving the quotation of product structural parts. One major expense in structural parts is molds, which require experienced engineers to evaluate the raw materials and processes needed to meet customer requirements. Such expertise is difficult to cultivate, with only a few “key players” in the company. Losing them could lead to significant setbacks.

Profet AI AutoML’s Ease of Use and Expert Advisory Enhance AI Analytical Skills

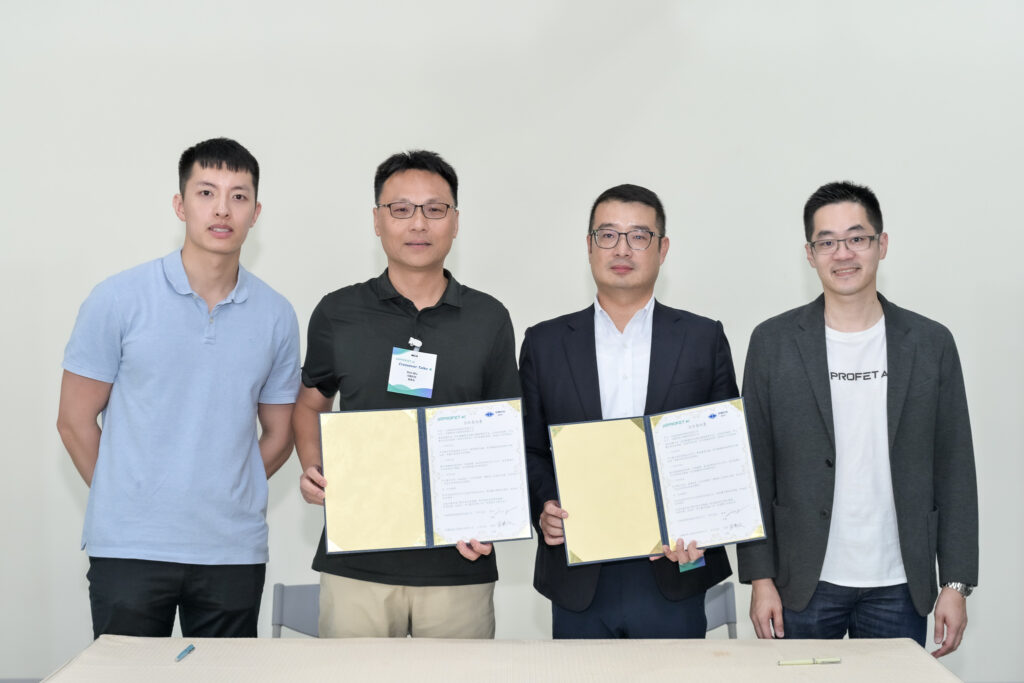

To significantly enhance efficiency and agility, Wiwynn introduced Profet AI’s AutoML Data Scientist Platform in early 2024. Part of the NVIDIA ecosystem, Profet AI’s platform was selected for its high usability—it requires minimal IT expertise to get started. Another reason was Profet AI’s team of consultants with extensive industry knowledge. Collaborating through AI-ML Thinking workshops with Profet AI consultants, nearly 100 domain experts at Wiwynn produced about 30 AI topics.

Although Wiwynn has trained some AI specialists, Yu admitted that these resources are insufficient to meet the demands of numerous AI projects. Furthermore, these specialists lack insight into the operations and challenges of various departments, such as manufacturing, sales, and finance. Profet AI’s consultants, with their deep industry knowledge and AI implementation experience, enable domain experts in different departments to quickly adopt AI.

“The value of consultants is in guiding teams to think,” Yu said. Profet AI’s consultants assist users in identifying areas where AI can be applied, clarifying key factors influencing AI, and pinpointing highly relevant data. Developing these analytical skills is something Wiwynn’s in-house AI talent could not achieve alone.

AI Workshops Attract Over 100 Participants, Boosting R&D Efficiency and Realizing AI-for-All Goals

Earlier this year, with Profet AI’s support, Wiwynn organized a series of AI workshops. Initially, 7–8 teams were expected to participate. However, within a month, over 20 teams and about 100 people signed up to explore AI topics for their respective departments. After months of validation, around 10 AI projects are expected to materialize.

In addition to AI applications in quotations, AI projects in engineering R&D and factories have also matured. During the workshop competition, one R&D team applied AI to thermal management. They’ve drastically reduced the time required to determine optimal parameters by half with the help of Profet AI’s platform. Another team proposed factory production line optimization, using the Profet AI platform to swiftly adjust line configurations, such as workstation layouts and machine allocations, achieving operational excellence.

Yu noted that months of AI workshops have led to increasing departmental engagement in AI initiatives. Moving forward, Wiwynn plans to recruit a second batch of AI seed talents and invest more in AI talent development. Currently, Wiwynn is collaborating with Profet AI consultants to establish a cross-departmental virtual organization called the “Center of Excellence (CoE).” This organization will facilitate knowledge sharing and experience exchange among employees involved in AI projects, supported by professional consultants to resolve challenges and accelerate AI implementation across departments.

After establishing a robust AI adoption mechanism in Taiwan, Wiwynn aims to extend this model to its global operations, fully realizing the chairman’s vision of “AI-for-All.”

Wiwynn Drives a Bottom-Up AI Culture with Profet AI, Rapidly Cultivating AI Talent 閱讀全文 »